Here’s a photo of the just the lower “manual” on the stand with the cut down 2nd Tier units attached:

I used a mallet to knock the “gears” off after removing the threaded rod/knob:

They are just pressure fitted. Tap it on one side a few times - then the other - it will pop off.

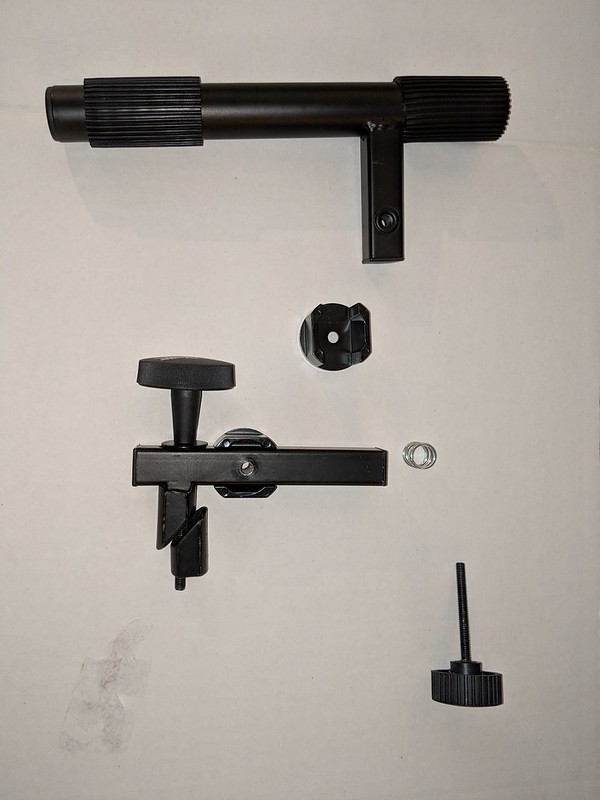

Here is are all the parts separated:

I wrapped masking tape around the upright tube where I wanted to cut it to make sure my hacksaw cut was square. I also cut the back extension of the horizontal round tube so when I put the mike attachment on it would be right up against the back of the upper keyboard. The laptop holder is screwed onto the mike holder.

I used a friend’s drill press to drill the new holes you see where the threaded rod/knob goes through.

One last comment - unfortunately the gears don’t position the horizontal tube at a 90 degree angle to the upright. I chose the slight angle from back upwards to front. I’m thinking about putting a piece of hard rubber between them and tightening it at 90 degreees.